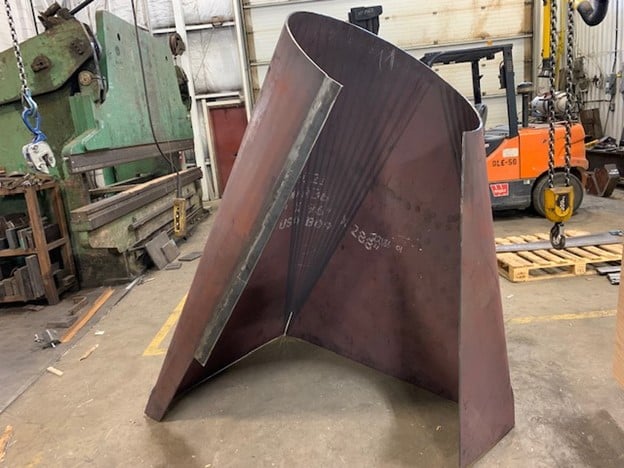

Recently one of our customers asked if we could form a large eccentric transitional chute. There were some challenges with this project due to the size and thickness. But the biggest challenge was to make the chute from a single piece without a weld seam. Due to abrasion dynamics, it’s advantageous to avoid weld seams in critical areas with some materials.

We planned through the forming sequence and our skilled press operators achieved success on this part that has portions of 4 sides.

Our 16’ press has 12’ 5” between the housings and this was also a key feature to accommodate this forming job.

Put us to work for you. We are very careful not to declare something that can’t be done until we’ve first examined it through the lens of achievement.