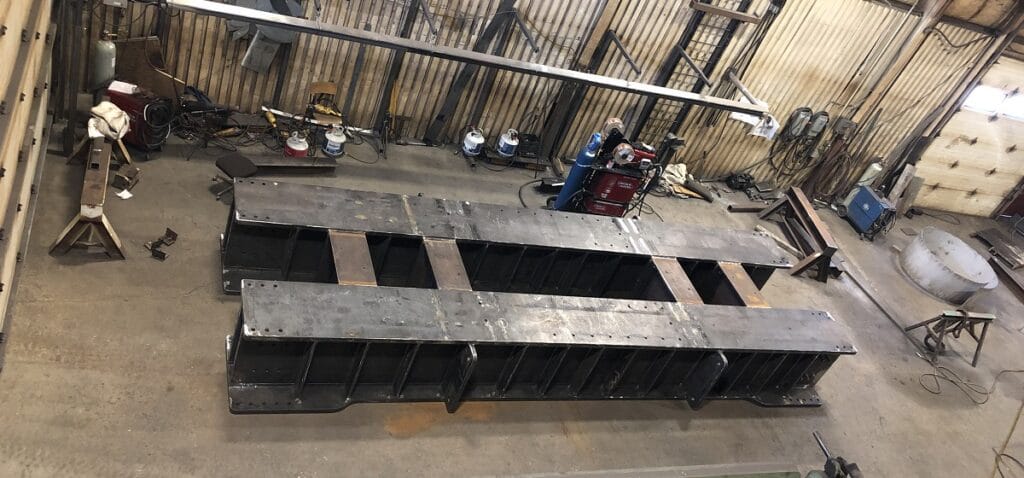

Contract with Saskatchewan engineering firm to build stainless steel ducting and stacks for a Saskatchewan ethanol plant.

The process involved a successful quotation from the Customer’s IFC drawings; this required design consultation and revision through to final design revisions and then shop drawings.

The project involved damper elements requiring specific geometry to work with actuators and trial fits to confirm movements. Additionally, the stacks were to stand at 100’ in height made from multiple components. Vertical plum was critical, so extra care and tight tolerances were followed in order to adhere to job requirements.

Challenges

The plant construction required the components to be delivered within a tight timeline for construction targets to be met.

Successes

As a Saskatchewan company, we are proud to have partnered with a Saskatchewan engineering firm to contribute to a Saskatchewan ethanol plant that uses Saskatchewan grains to generate the future’s fuel all here at home!