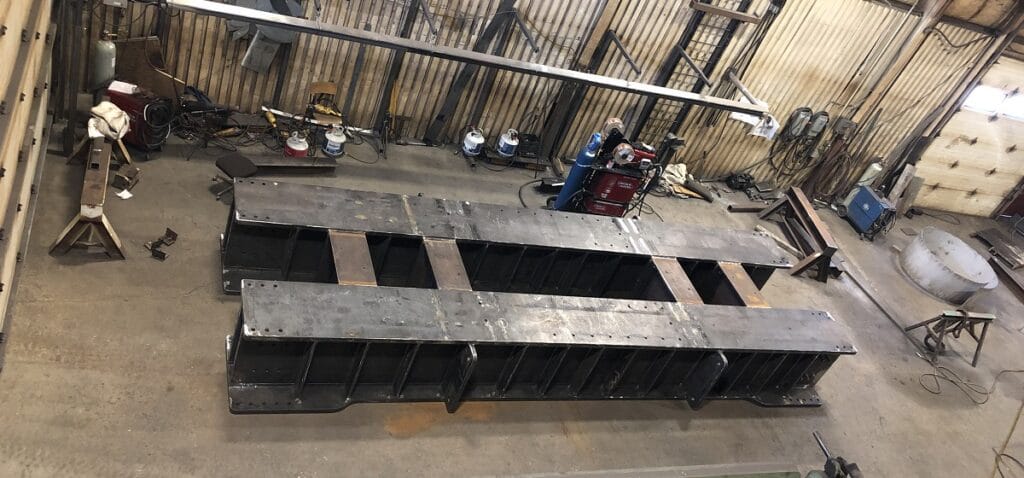

Rush replacement cone maintenance repair for an Alberta pulp mill.

Cone material was 5/8” thick and needed to be formed in segments that could be easily moved into place at an existing mill. The cone parts were beveled for weld prep and were ready to assembly on site.

Our project management team sent a quotation when the rush RFQ was received. After receipt of order, we prepared shop drawings and purchased the cut pieces. The cone parts were formed and beveled. The collar was rolled and welded with full penetration.

Challenges

Sourcing the material and delivering the required parts within the deadline.

Successes

Considering the short allowable maintenance downtime, and the restrictive work environment space, we worked within very tight tolerances and produced the required parts in 6 business days from receipt of order.